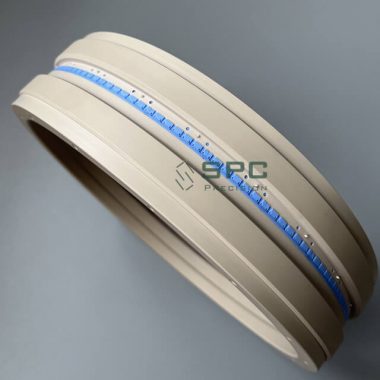

Spot Plating Drum used in REEL to REEL Selective Plating/Hoop Plating

Reel to reel selective plating is an efficient and economical way of plating. It is a unique process that allows for precise deposit of metal on stamped product. It provides several valuable benefits that other plating methods do not.

Constantly escalating prices of gold, palladium, silver, and other metals have made precious metal conservation essential.

Manufacturers of connectors, capacitors, and other electrical components continuously search for innovative ways to reduce costs.

The parts will be masked in all locations except the areas that require selective plating. Limiting precious metals, such as gold and palladium, to critical locations greatly reduces the amounts used during the electroplating process, thereby reduces costs.

REEL to REEL Selective Plating /Hoop Plating

In the field of reel-to-reel continuous selective plating, we have accumulated many years of experience. So that we can design the most cost-effective selective plating tools for parts of various materials and complex structures.

– Selective Spot plating

– Selective Stripe plating

Metals used with selective plating

Gold-plated products are generally: DDR, BTB, FPC, BATTERY, MNI-CARD, USB, PCI, JACK and other sheet continuous selective plating;

Silver-plated products are generally: LED, SOT, lead frame and other continuous selective electroplating.

SPC Precision can supply unique selective plating tools solutions to your specific plating needs.

– PEEK spot plating wheel, PEEK Plating fixture, PEEK stripe plating tools.

The advantages of SPC PEEK selective plating wheels

1. High temperature resistance. The continuous use temperature of PEEK is 260 degrees Celsius.

2. Excellent anti-friction and wear resistance. The PEEK plating wheel is highly electroplated with the guide roller and tension control belt. At this speed and pressure, the PEEK plating wheel can guarantee a minimum life of two years.

3. Chemical resistance. The chemical components in the electroplating environment are generally gold, silver, potassium cyanide, citric acid, conductive salts, balanced salts, etc. PEEK plating fixture will not corrode at all under these chemicals.

4. Hydrolysis resistance. PEEK plating tools can resist damage caused by water or high pressure steam, PEEK plating tools can be used continuously in high temperature and high pressure water and maintain good mechanical properties.

5. SPC Precision can provide PEEK tubes pipes for a wide range of dimensions to help customers reduce material cost.

The most common sizes of PEEK tube used to selective plating wheel are,

– OD260mm x ID220mm, L 62mm or 82mm, or 102mmor others

– OD285mm x ID225mm, L 202mm or others

– OD300mm x ID256mm, L 62mm or 82mm, or 102mmor others

– OD362mm x ID280mm, L 112mm or others

– OD362mm x ID311mm, L 202mm or others

– Customized sizes are available!

PEEK material properties

| Variation of thermal expansion coefficient at different temperatures | |||||

| 20℃ | 50℃ | 100℃ | 150℃ | 200℃ | |

| PEEK-N | — | 4.62*10-5℃ | 4.66*10-5℃ | 4.8*10-5℃ | 6.33*10-5℃ |

| Effect of different acidic solutions on material size | |||||

| Solvents | PEEK-N | ||||

| 15%HCI | -0.01mm | ||||

| 15%H2SO4 | -0.001mm | ||||

| 20%H2SO4 | -0.02mm | ||||

| 20%HNO3 | -0.01mm | ||||

| Material properties | |||||

| Item | Test Standard | PEEK-N | |||

| Mechanical properties | |||||

| Tensile strength (Mpa) | ISO 527-2 | 102 | |||

| Elongation at break | ISO 527-2 | 14.5% | |||

| Bending strength (Mpa) | ISO 178 | 173 | |||

| Impact strength( KJ/M2) | ISO 179-2 | No Break | |||

| Thermal properties | |||||

| Melting point | ISO 11357 | 334℃ | |||

| Glass transition temperature | ISO 11357 | 143℃ | |||

| Long time using temperaature | UL 74685 | 260℃ | |||

| Electrical properties | |||||

| Dielectric strength | IEC 602431(2mm) | 19 | |||

| Dielectric constant | IEC 60250(1KHz) | 3.2% | |||

info@spcprecision.com

info@spcprecision.com