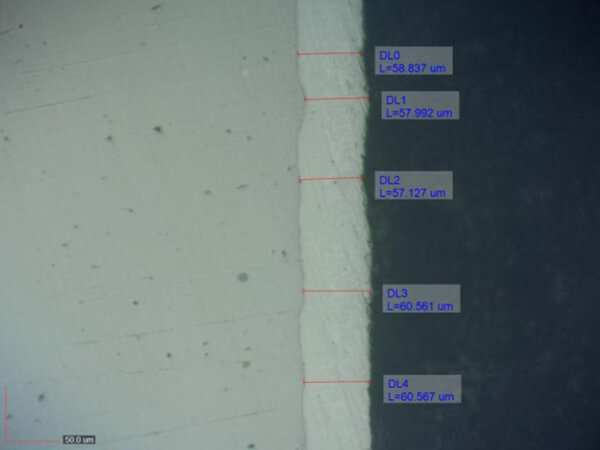

1. Metallographic method

A method of measuring the local thickness of the metal cover layer and the oxide film layer by detecting the cross section with a metallographic microscope. Generally, the thickness needs to be greater than 1um to ensure that the measurement results are within the error range; the larger the thickness, the smaller the error.

2. Coulomb method:

Anodic dissolution coulomb method suitable for measuring the thickness of single and multi-layer metal plating, including the measurement of multi-layer systems such as Cu/Ni/Cr as well as the thickness of alloy plating and alloyed diffusion layers. It can measure not only the thickness of the cover layer of flat specimens, but also the thickness of the cover layer of cylindrical and wire rods, especially suitable for measuring the metal and its potential difference of multi-layer nickel plating. The types of measurement coatings are Au, Ag, Zn, Cu, Ni, dNi, Cr.

3. X-Ray Fluorescence

It is suitable for measuring the thickness of metal covering layers that need to be analyzed in industries such as electroplating and electronic circuit boards. Including: gold (Au), silver (Ag), tin (Sn), copper (Cu), nickel (Ni), chromium (Cr) and other metal element thickness.

Test principle

1. Metallographic method:

Using the principle of metallographic microscope, the thickness of the coating is enlarged for accurate observation and measurement

2. Coulomb method:

Using a suitable electrolyte anode to dissolve a precisely defined area of the cover, a sharp change in cell voltage indicates that the cover is substantially completely dissolved, and the thickness of the cover is calculated from the amount of electricity consumed. Depending on the method of anodic dissolution, the amount of electricity consumed by the thickness of the measured coating varies. When dissolving with a constant current density, it can be calculated from the time from the start of the test to the end of the test; when dissolving with a non-constant current density, it is calculated from the accumulated power consumption, which is displayed by the electricity meter.

3. X-ray method:

The X-ray spectroscopic method for determining the thickness of the plating is based on the interaction of an intense and narrow beam of polychromatic X-rays with the substrate and the plating. This interaction produces secondary radiation of discrete wavelengths and energies characterized by the elements that make up the plating and the matrix. There is a certain relationship between the mass per unit area of the cover layer (the linear thickness of the plating if the density is known) and the secondary radiation intensity. This relationship is first determined by calibration of the overlay calibration block of known mass per unit area. If the density of the cover material is known and the actual density is given, such a standard block will give the linear thickness of the plating.